Grasl Pneumatic-Mechanik GmbH

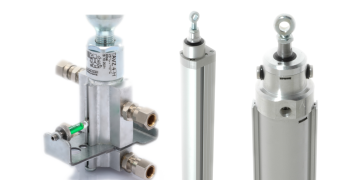

Our company is run by the third generation of the Grasl family. It is based in Reidling, Lower Austria. It was founded in Heiligeneich in 1963. Our core competencies include the manufacture of pneumatic cylinders, pneumatic valves, electric actuators, opening fittings, and pneumatic and electrical controls for preventive fire protection, smoke and heat extraction systems, as well as for daily ventilation.

We offer our customers not only high product quality, but also competent consulting services, fast processing times and customized solutions for specific requirements.

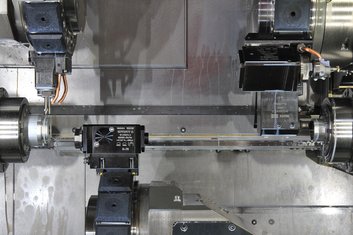

We develop our own products, which we manufacture regionally and sell internationally. We strive for a high level of production depth with a high proportion of in-house production. Our machinery is constantly being expanded with the latest technology and is state of the art.

Continuous and stable growth ensures the long-term existence of the company. We develop new markets and maintain existing customer relationships so that our customers are strengthened in their cooperation with us.

We pay particular attention to our product quality as reliable and innovative functions are of great importance in fire protection. In everything we do, we pay attention to respectful interaction and mutual understanding.

Partnership K + G Tectronic GmbH

Our passion. Your safety.

A long-standing, successful cooperation exists with K + G Tectronic GmbH in Eschweiler, Germany in the areas of electronics manufacturing and sales.

Our electronic products include SHEV control centres and controls, electrical actuators and all peripheral devices that complete, expand and optimise the functional scope of SHE and ventilation systems.

Competencies and resources

We have many years of experience in the development, certification and manufacture of fire protection products.

We use modern 3D CAD software for design, strength and flow simulation. We are also supported in product development by fully automated test benches, cold chambers and laboratory furnaces.

In production, we use highly productive multi-spindle lathes and milling machines, CNC punching machines and folding presses with bending robots. For quality control, we use universal tactile and optical 3D coordinate measuring machines. Our ISO 9001-certified company also has numerous calibrated measuring devices at its disposal.

Digital production orders set the pace in our assembly department. Before delivery, many of our products are tested for functionality on automatic test benches. The results of the tests are linked to the digital order.

Grasl Pneumatic-Mechanik GmbH stands for quality, reliability and innovation and is the ideal partner for demanding projects in the field of preventive fire protection. Certification according to ISO 9001 and numerous product recognitions express this claim (VdS certificates).

Training

In our company, we train apprentices in the mechatronics and metal technology trades, imparting a wide range of knowledge in various technical fields. An apprenticeship as a mechatronics technician is a good choice, as it lays a solid foundation for a successful career. The combination of mechanical engineering, electronics, and computer science allows you to participate in complex projects and understand various systems.

Have we piqued your interest? You can find more information in our Mechatronik Flyer.

Jobs

We are looking for reinforcements for our production team as well as product development and are always happy to receive applications to reinforce our team, we welcome applications by mail at any time personal@graslrwa.at.